BACKGROUND

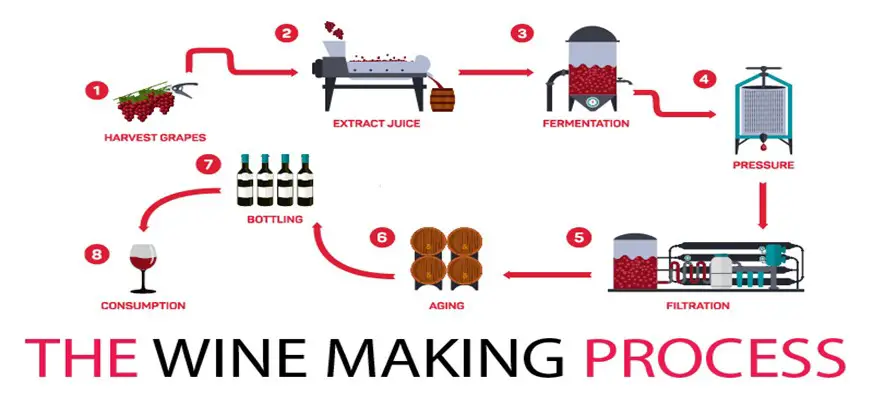

Wine making is the production of wine, starting with the selection of fruit, its fermentation into alcohol and finally bottling of the final finished liquid. Alcohols are vital industrially and commercially. Commercial alcohol includes Methanol, Ethanol, Isopropanol, and Ethylene Glycol.1

So the basic objective of the test is to carry out the production of wine by the process of fermentation.

REQUIREMENTS

Chemicals: Corn steep glucose, Glucose

Apparatus: Fermenter, Centrifuge

PROCEDURE

Commercially fermentation is the initial step for production of wine, beer and cider.

Harvesting

It is the first step in wine making process. Grapes are the only fruit that contain the necessary acids, tannins, esters which are required to make a natural wine. Tannins are textural elements that make the wine dry & add astringency and bitterness to wine.2

The acidity, flavour and sweetness of the wine is determined the moment the grapes are picked. The harvesting can be done by hand or mechanically. More preferable is harvesting by hand as the mechanical process can be rough on the grapes & the vineyard. It should be ensured that the rotten or under ripe grapes are removed.

Squashing

After the grapes are sorted they are then de-stemmed and squashed.3 Previously they were squashed by stomping with the feet, but now it is done mechanically by mechanical stomping which is known as Must. Must is the fresh pressed grape juice that contains the skins, solids, seeds.

Mechanical stomping has improved the sanitation of the wine as it avoids contamination and thus has increased the quality of the wine.

Fermentation

This is the most vital part of the production of wine. After squashing, fermentation takes place. Fermentation begins naturally within 6-12 hours when aided with yeast in the air.4 The fermentation continues until all the sugar is completely converted into alcohol and dry wine is produced.

To create sweet wine the process is stopped before all the sugar is converted completely. Fermentation takes place for a long period of time.5

Clarification

It is the process in which solids such as yeast cells, tannins and proteins are removed. Wine is transferred into a different stainless steel tank. Wine is then clarified by filtration. Filtration occurs by using a filter to capture the larger particles in the wine. The clarified wine is then transferred into another vessel and prepared for bottling or for future aging.

Bottling and aging

Bottling is the final stage of wine making process. Aging of the wine can be done in bottles, stainless steel tanks or oak barrels. Aging in oak barrels produce smoother, rounder and more flavoured wine which thus increases wine’s exposure to oxygen while it ages, which decreases tannin & helps the wine reach its optimal fruitiness.

CONCLUSION

Wines are generally bottled with either a cork or a screw cap for aging.

The wine making process. (Source:

https://oceania.ohaus.com/en-OC/About-Us/News/The-Wine-Making-Process-and-the-Perfect-Pour)

REFERENCES

- G. Van den Thillart, Verhagen Maria, Waarde V.A. Ethanol formation and pH regulation. 1993: 157-170.

- Gemma B, Maria J.T., Maite N, Noemi, Nicholas R. Analysis of Yeast Populations during Alcohol Fermentation. Systematic & Applied Microbiology. 2002:287-293.

- Jackson, Ronald S. Wine Science Principles And applications. 2008: 277.

- Segal K, Alba L.;”Yeast fermentation and making of beer and wine”.2010: 3(9):17.

- Van J, Jacobs C. Killer yeasts in the wine industry. American Journal of encology and viticulture. 1992: 3;119-128.

Also read:

- Determination of saponification value of the given oil/fat

- Determination of saponification value of fat (coconut oil)

- Protein denaturation by egg albumin method (in vitro)

- Analgesic activity study of drugs by hot plate (Eddy’s hot plate) method

- Study of local anesthetics by Infiltration anaesthesia in guinea pig

- Study of local anesthetics by Surface anaesthesia on the cornea of rabbits

- Study of local anesthetics by Spinal anaesthesia in rats

🔴 Would you like to attempt Labmonk Daily quiz? Click here

🔵 Check out Jobs & Exam Notices. Labmonk Notice Board

🔴 Labmonk Scholarships. Click here

🔵 Labmonk Blog. Click here

🔴 Do you need notes? Click here

🔵 Watch Career related videos on Youtube: Watch now !!

🔴 Would you like to answer Labmonk quiz? Click here